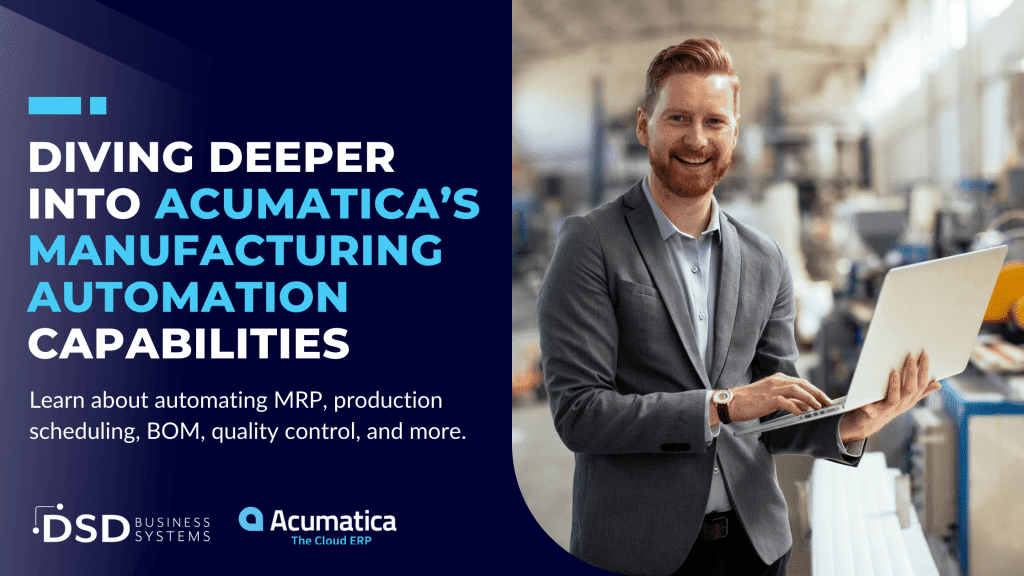

Diving Deeper into Acumatica’s Manufacturing Automation Capabilities

September 7, 2023

by Jared Bollier, Digital Marketing Analyst

Manufacturing has always been an intricate dance of parts, processes, and people. Today, with the rise of Industry 4.0 and the integration of digital technologies into production lines, automation has become the linchpin for modern manufacturing success. Acumatica, as one of the leading cloud-based ERP solutions, has recognized this shift and offers a suite of manufacturing automation capabilities that are nothing short of transformative. Let’s dive deep into what Acumatica brings to the table.

Acumatica Automation Capabilities

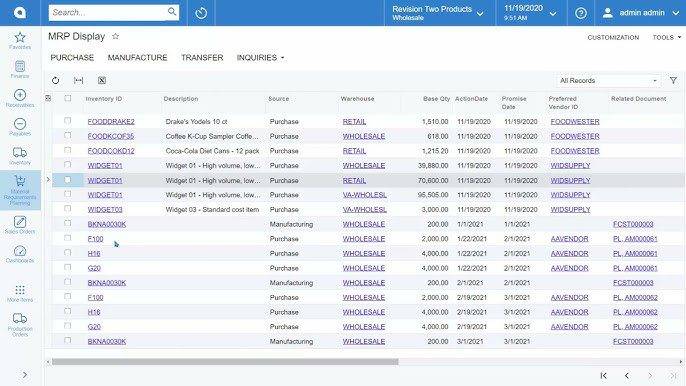

Material Requirements Planning (MRP)

At its core, Acumatica’s MRP automates the complex process of determining what materials are required, how much is needed, and when they should be procured or produced. By considering multiple factors like current inventory levels, pending sales orders, and production schedules, Acumatica aids businesses in making informed purchasing and production decisions. Learn more.

Automated Production Scheduling

Acumatica’s advanced scheduling features allow manufacturers to optimize production timelines. By automatically allocating work centers, machines, and labor, Acumatica ensures that the entire production process is streamlined, reducing idle times and enhancing productivity.

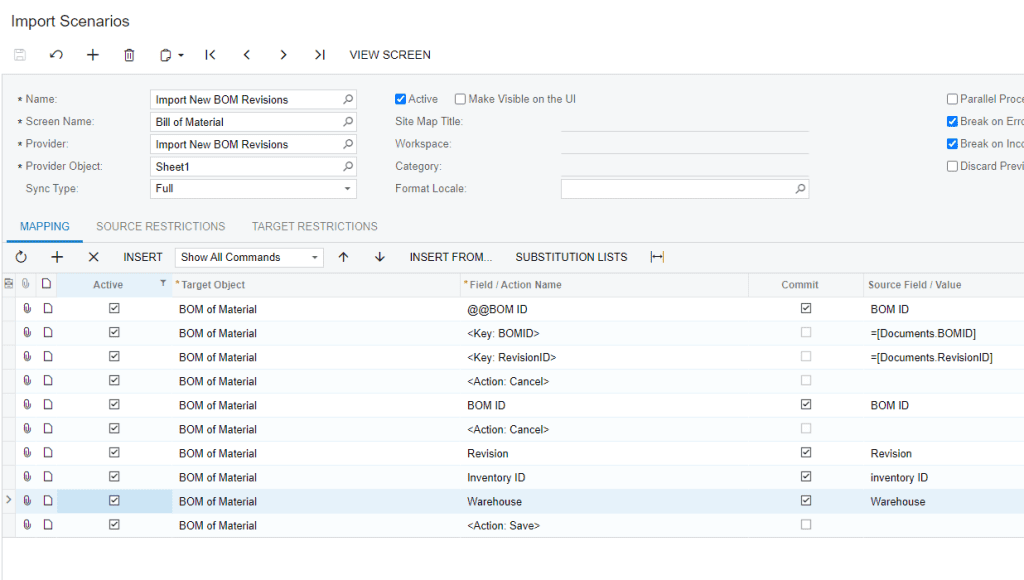

Bill of Materials (BOM) Automation

The BOM management in Acumatica enables automatic updates, revision control, and real-time visibility into production costs. This not only reduces the chances of errors but also ensures that production runs smoothly, even when there are last-minute changes or disruptions. Learn more.

Quality Control Automation

To ensure that manufactured products meet the desired standards, Acumatica integrates automated quality control checks throughout the production process. This includes automated data collection from machines, real-time monitoring, and instant alerts for any deviations from set quality parameters.

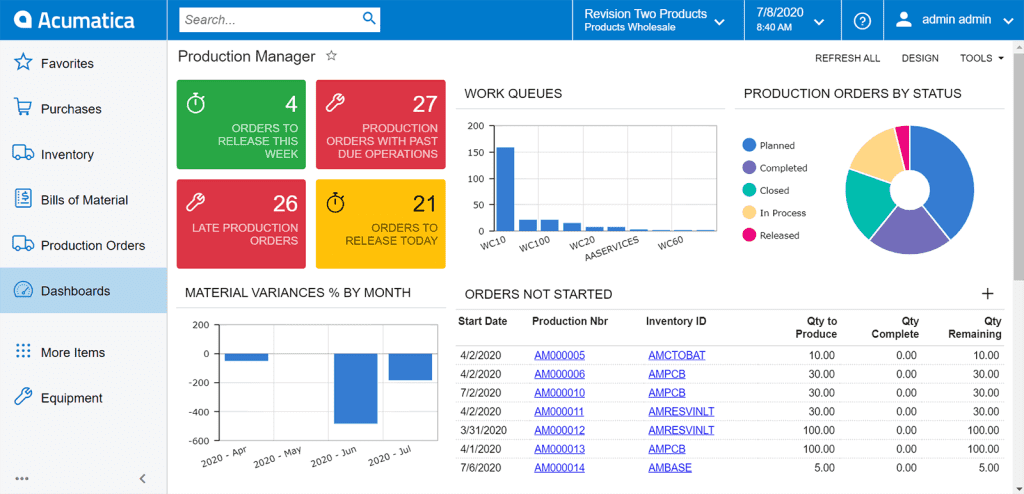

Real-time Analytics & Reporting

One of Acumatica’s standout features is its real-time data analytics capability. By integrating data from various departments – from sales to production – Acumatica offers insightful, automated reports. This empowers decision-makers with up-to-date information, facilitating faster and more accurate decisions.

Shop Floor Data Collection

Incorporating IoT devices and sensors into the production line, Acumatica automates the collection of crucial shop floor data. This includes machine uptime, downtime reasons, production counts, and more. This real-time data feed helps in better production tracking and performance analytics.

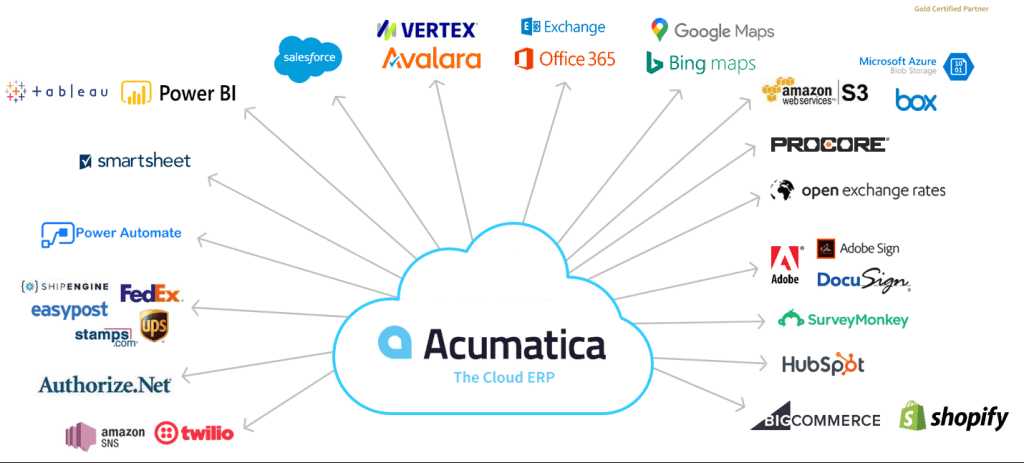

Seamless Integrations

Manufacturing doesn’t function in isolation. Acumatica understands this and offers automated integrations with CRM, finance, e-commerce, and more. This ensures that data flows seamlessly across departments, eliminating manual data transfers and potential discrepancies.

Inventory Management & Automation

Acumatica’s inventory management tools automatically track stock levels, set reorder points, and even suggest purchase orders. This ensures that manufacturers maintain an optimal inventory level, reducing carrying costs and avoiding stockouts. Learn more.

Automate your Operations

In a world where manufacturing competitiveness hinges on efficiency, agility, and data-driven decisions, Acumatica’s manufacturing automation capabilities are a boon. By seamlessly intertwining production processes with digital intelligence, Acumatica not only promises streamlined operations but also a clear pathway to manufacturing excellence.

Manufacturers looking to embrace the future and stay ahead of the curve would do well to explore Acumatica’s offerings. Because in the modern age, automation isn’t just an option – it’s an imperative.