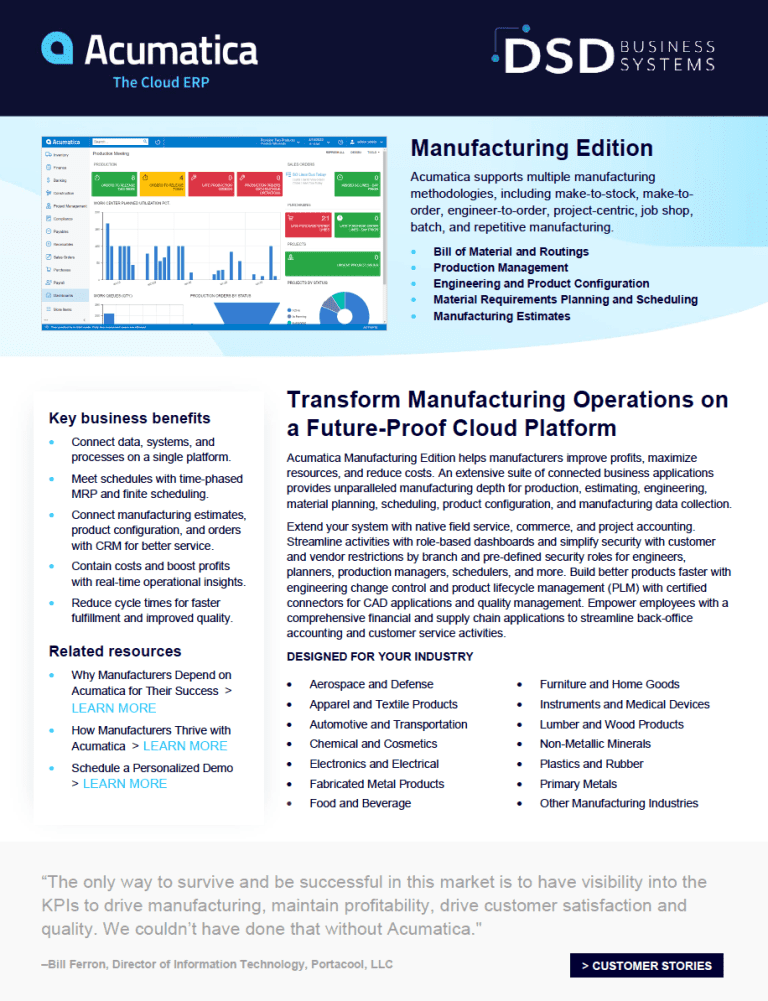

Acumatica Manufacturing Edition

Acumatica Manufacturing Edition fully supports multiple manufacturing processes that integrate production planning and shop floors with customer management, sales orders, inventory, purchasing, accounting, and financial reporting. As a result, Acumatica ERP Cloud software provides real-time coordination of activities across an entire business. This means staying connected to production orders, schedules, and material plans anywhere, anytime on the road, in the office, or at home.

Acumatica Cloud ERP Software for Manufacturers

Acumatica Manufacturing Edition helps manufacturers improve profits, maximize resources, and reduce costs. An extensive suite of connected business applications provides unparalleled manufacturing depth for production, estimating, engineering, material planning, scheduling, product configuration, and manufacturing data collection.

Track material, outside process, and labor costs by work order. Compare the estimated/planned/standard production costs to the actual costs of the production order. Maintain lot and serial traceability throughout the item’s lifecycle with preassigned lot and serial numbers for finished goods.

Material Requirements Planning (MRP) generates time-phased manufacturing and purchasing plans for optimal inventory availability tied to demand forecasts and customer demand. Reduce inventory while improving customer service. Manage plans by site or across multiple locations.

Improve manufacturing estimate accuracy. Integrate estimates with CRM quotes and create estimates using material, overhead, labor, and other miscellaneous costs. This is an optional module.

Streamline the creation of complex bills of material and routings with the rules-based product configurator. Use options and values to configure finished goods. This is an optional module.

Schedule labor operations against finite capacity constraints. Use rough-cut capacity planning (RCCP) to verify capacity requirements for the master schedule. Visualize your production schedule with a graphical view of production order schedules by work center and machine. Adjust constraint dates and priorities and firm schedules from the visual schedule board. Maximize work center utilization and manage bottleneck resources with scheduling inquiries and reports. This is an optional module.

Print barcoded reports and labels to scan material movement and labor transactions directly from the shop floor in real-time.

Centrally manage sales activities such as quote entry, sales order fulfillment, shipment creation, and price management. Reduce costs and improve vendor relationships by automating and centralizing purchasing processes. For example, automate purchase requests and obtain vendor bids.

Manage inventory receipts, warehouse transfers, and transfers to production orders. Track inventory by warehouse, bin, and location with cradle-to-grave lot and serial traceability. Manage inventory valuations, perishable inventory expiration dates, and use matrix items to manage product families.

Thrill customers and shorten sales cycles with embedded CRM for a 360-degree view of customer relationships and activities. Generate more leads with marketing automation and shorten sales cycles with real-time insights into manufacturing sales activities.

Acumatica Product Tour

Do you want to see a demo now? In this 8 minute product tour, you can expect:

Bill of Materials Management: Acumatica supports multiple bills of materials and revisions, allowing for detailed specification of operations, material requirements, and scheduling.

Production Order Details: : Users can access detailed information about production orders, including quantities, dates, and related costs.

Material Requirements Planning (MRP): The MRP feature provides a comprehensive view of material planning, taking into account all supply and demand aspects. It also includes the ability to create purchase and manufacturing orders directly from the MRP screen.

Dashboard and Scheduling Tools: The Manufacturing Edition includes powerful dashboards for monitoring shop floor activities and a production schedule board for identifying bottlenecks.