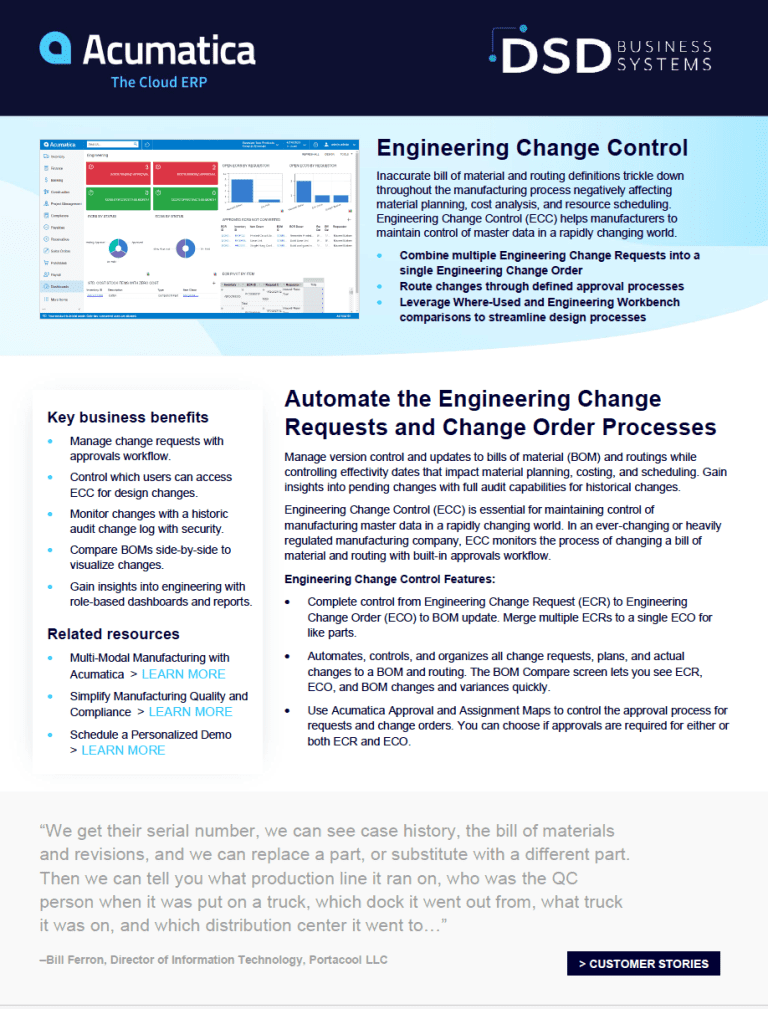

In this Acumatica Engineering Change Control Brochure, learn how Engineering Change Control (ECC) is an essential requirement for maintaining control of manufacturing master data in a rapidly changing world. In an ever-changing or heavily regulated manufacturing company, ECC monitors the process of changing a bill of material and routing with built-in approvals workflow.

Manage version control and updates to bills of material (BOM) and routings while controlling effectivity dates that impact material planning, costing, and scheduling. Gain insights into pending changes with full audit capabilities for historical changes.

Acumatica Control Features:

Complete control from Engineering Change Request (ECR) to Engineering Change Order (ECO) to updating the BOM. Merge multiple ECRs to a single ECO for like parts.

Automates, controls, and organizes all change requests, plans, and actual changes to a BOM and routing. The BOM Compare screen allows you to see changes between ECR, ECO, and BOM quickly.

Use Acumatica Approval and Assignment Maps to control the approval process for both requests and change orders. Along with that, you can choose if approvals are required for either or both ECR and ECO.

Key Topics in Engineering Change Control: