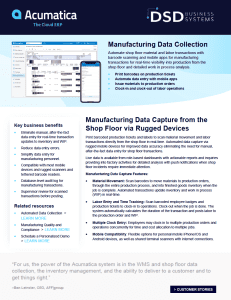

Manufacturing Edition:

Data Collection

Automate shop floor data entry for material and labor transactions.

Automate and Streamline Data Collection with Barcodes, Scanners, and Mobile Devices

Print barcoded reports and labels to scan material movement from raw material inventory into production, through downstream manufacturing operations, and into finished goods inventory when production is complete. Clock-in and clock-out of jobs to capture labor transactions to update work in process (WIP).

Key Benefits of Acumatica Manufacturing Data Collection

Real-Time Inventory

Automated data collection updates inventory in real-time eliminating confusion regarding what’s on hand or how many are available.

Eliminate Data Entry Errors

Barcode scanning eliminates after-the-fact data entry for material movement as well as labor transactions.

Versatile & Device Agnostic

Manufacturing Data Collection is compatible with iPhone/IOS, Android, and other mobile, internet-compatible barcode scanners.

Important Features of Acumatica Manufacturing Data Collection

Scan barcoded employee badges and production tickets to clock-in to operations.

Clock-out when the job is done.

The system automatically calculates the duration for the transaction and posts labor to the production order and WIP.

Scanned transactions can optionally be reviewed by supervisors facilitating data correction prior to posting to the database.

Works with mobile iPhone/iOS, Android devices, and scanners supporting internet connections.

Create a sales order directly from the estimate.

Set defaults for automated data capture transactions such as setting the default order type for automated scans; using the required quantity of materials as defined in the production ticket bill of materials for move transactions; mandatory location selection for material transactions; confirmation by line; use default warehouse; use default auto-generated lot or serial numbers; use default expiration date; and more.